The global energy landscape is shifting from traditional fossil fuels to renewable energy, highlighting the urgent need for efficient energy conversion and storage technologies. Lithium-ion batteries (LIBs) have become core components in electric vehicles and stationary energy storage systems. However, with the widespread use of LIBs, the increasing number of spent batteries presents significant challenges both in waste management and environmental protection, particularly due to the difficulty in recovering valuable metals embedded in spent LIBs. Compared to traditional pyrometallurgical and hydrometallurgical methods, which are energy-intensive and inefficient, converting waste lithium into advanced functional materials offers a promising solution. Similarly, the accumulation of plastic waste poses a severe global environmental threat. Solar-driven photothermal plastic upcycling has shown great potential for sustainable plastic reuse. Photothermal catalysts can absorb solar energy and provide enhanced catalytic activity. However, the challenge remains on how to achieve the simultaneous recycling of both plastic waste and spent batteries, improving energy efficiency while reducing environmental impact.

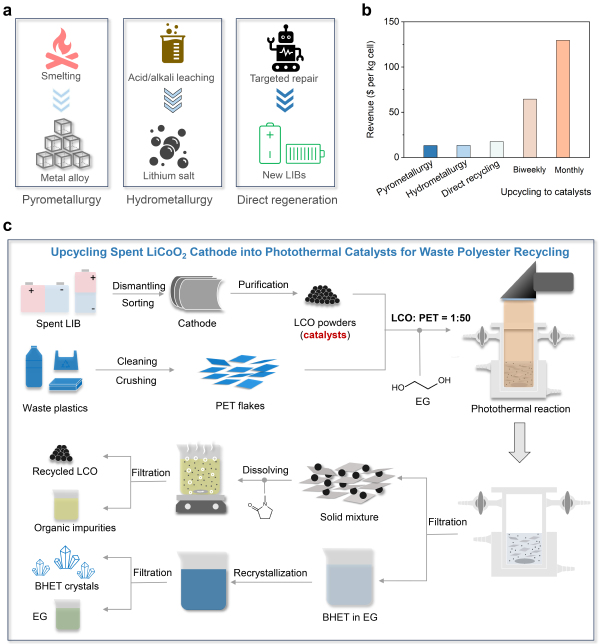

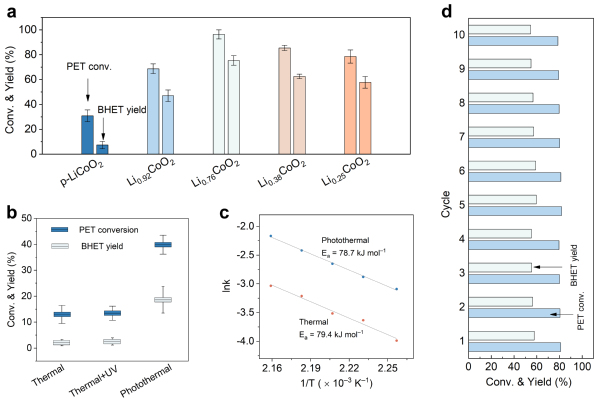

To address these challenges, Professor Jinxing Chen from the Institute of Functional Nano & Soft Materials (FUNSOM) at Soochow University, and Dr. Panpan Xu from the Suzhou Institute of Nano-Tech and Nano-Bionics, Chinese Academy of Sciences, proposed a novel technology that converts spent lithium cobalt oxide (LCO) cathode materials into photothermal catalysts. This technology not only efficiently catalyzes various waste polyester materials, upcycling them into high-value monomers, but also provides a promising alternative to traditional recycling methods. In practical applications, the researchers simulated the structural changes in LCO during prolonged battery cycling through chemical delithiation and found that as the degree of delithiation increased, the chemical valence of Co in LCO gradually rose, significantly enhancing the efficiency of its photothermal catalytic PET glycolysis to produce BHET. A comprehensive life-cycle assessment highlighted the economic feasibility of using waste LCO as a photothermal catalyst, generating a return of $129.6 per kilogram of LCO, surpassing the return from traditional battery recycling methods ($13–17 per kilogram of LCO). This dual-recycling strategy combines key metal resources from spent batteries with plastic waste, improving energy recovery efficiency while reducing environmental impact. This synergistic recycling approach not only offers new solutions for the circular use of spent lithium batteries and plastics but also advances sustainable resource utilization and promotes the principles of the circular economy. The related findings were published in the journal Nature Communications (Nat. Commun. 2024, 15, 2730).

Fig.1 Upgrading spent LCO cathodes to catalysts.

Fig 2. Photothermal catalytic PET glycolysis over Li1-xCoO2.

Link to paper: https://doi.org/10.1038/s41467-024-47024-x

Title: Grave-to-cradle photothermal upcycling of waste polyesters over spent LiCoO2

Authors: Xiangxi Lou#, Penglei Yan#, Binglei Jiao#, Qingye Li, Panpan Xu*, Lei Wang, Liang Zhang, Muhan Cao, Guiling Wang, Zheng Chen, Qiao Zhang, Jinxing Chen*

Editor: Danting Xiang, Xin Du